Film Capacitor

Capacitors are an essential passive component of electrical circuits because of their wide range of applications. Moreover, selecting a suitable type of capacitor for a circuit is necessary as capacitors are divided into different types based on their structure and composition. Film capacitor is one of the types of capacitors that has a long shelf life, low self-inductance, and can absorb the power surges in the circuits without getting damaged.

Outline:

What is a Film Capacitor

Construction and Working of Film Capacitor

Types of Film Capacitors

Self-healing Feature of Film Capacitors

Snubber Circuit

Power Filters

EMI Filters

Conclusion

What is a Film Capacitor

A film capacitor is one having a plastic film as the dialectic between its plates which makes it less expensive and keeps its characteristics constant for a longer time. This plastic film is quite thin as it has a thickness of one micrometer. This capacitor falls under the category of the nonpolarized capacitor, and this makes it pretty useful in AC circuits. The film capacitors can withstand overvoltage that is twice their rated voltage capacity.

Construction and Working of Film Capacitor

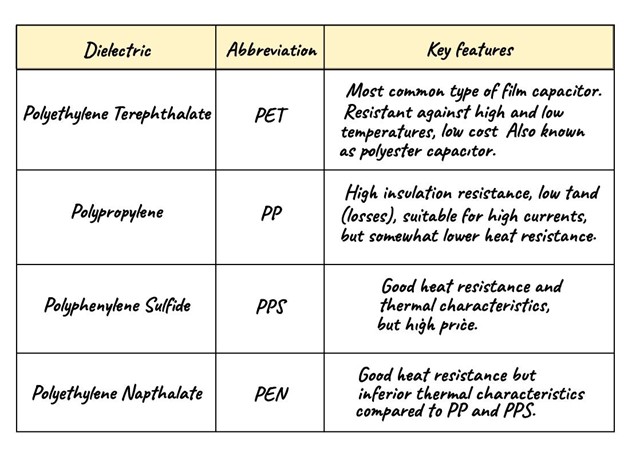

There are different types of plastic films used in a film capacitor which have different characteristics, for instance polypropylene film provides higher insulation resistance and is suitable for circuits having higher currents. Moreover, polypropylene sulfide comes with high heat resistance and good heat characteristics but is expensive. So here are the types of films with their characteristics that are used as dielectric in film capacitors:

Type of Film Capacitors

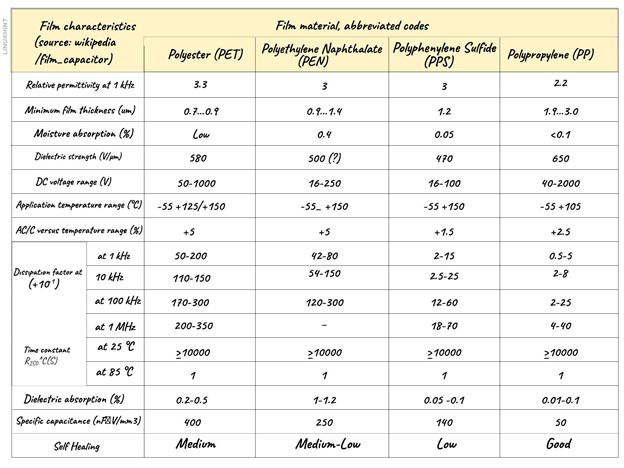

Now based on the dielectric film material of the film capacitor, its characteristics vary a lot so here is a table that displays the characteristics of film capacitors based on different types of insulating material:

To further illustrate the construction of capacitors there are two types of film capacitors one is foil film capacitors and the other is metallic capacitors or vapor deposition capacitor:

Foil Film Capacitors

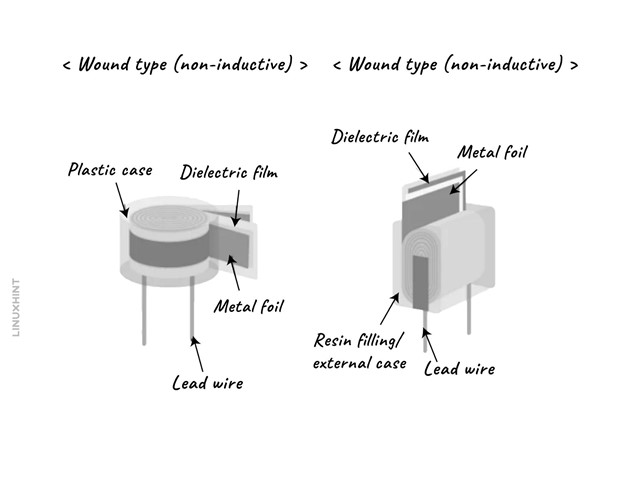

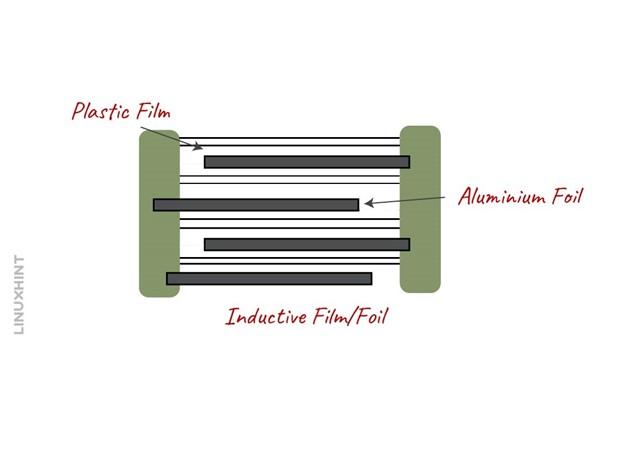

This type of capacitor has electrodes that are made from metal foil, and which are sandwiched between the plastic foils of the dielectric. These are wound-type film capacitors that can either be inductive or non-inductive and the difference between the two is that the target inductive foil film capacitor has its terminals directly connected to electrodes before winding. Whereas the non-inductive foil film capacitor has terminals that are connected to the end faces.

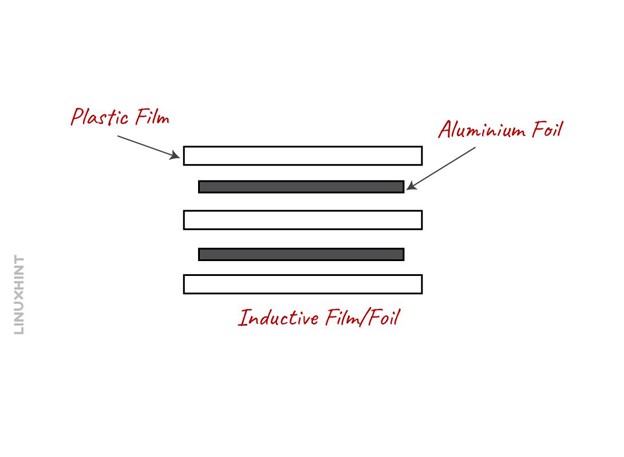

The non-inductive foil electrode film capacitors exhibit lower inductance and have high-frequency characteristics as compared to the inductive ones. In the inductive foil film capacitor, the metal foils are placed between two plastic films and are not directly connected:

Whereas in the non-inductive foil film capacitor, the metal foils are placed in such a way that each foil is placed a certain degree from the plastic films of dielectric:

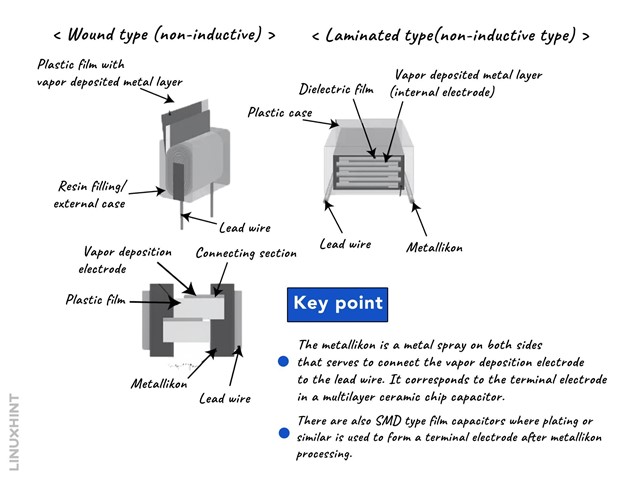

Metallized Film Capacitor

Another type of film capacitor is the metalized film capacitor, as it has a thin metallic layer that is sprayed on one side of dielectric plastic film. This deposited layer of metal on the plastic film creates an electrode of capacitors that is quite thin which makes it a lot smaller than the electrode-type film capacitor. These capacitors are only non-inductive type but can be either wound type or laminated type:

The film capacitor works the same as the general capacitor, that is when a power supply is connected to it the potential between the two electrodes begins to build up. When the charge on both plates is accumulated to their capacity it means that the capacitor is fully charged. Further, these film capacitors come with a self-healing feature which adds to their shelf life.

Self-healing Feature of Film Capacitors

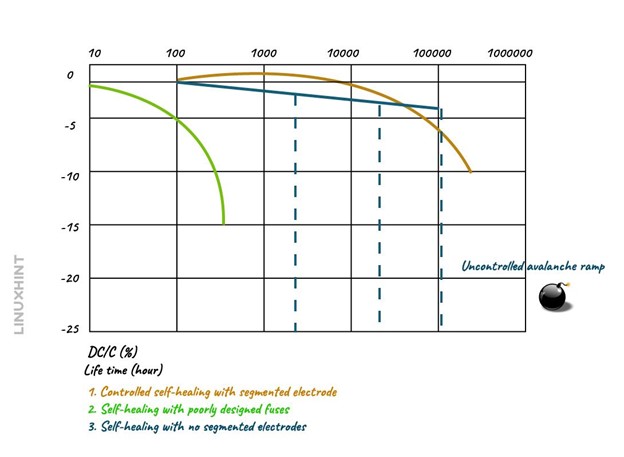

Whenever the insulation is de-metalized due to high current, high temperature, or any overvoltage the film capacitor oxidizes the surrounding deposited film. This separates the rest of the capacity area from the faulty one and thus keeps on functioning properly:

However, this isolation of the fault area from the rest of the capacitor can also decrease the capacitor’s capacitance over time. Further, there is a table below that shows the degradation of the capacitor capacitance over time due to the oxidation:

Here in the table above the blue graph shows the capacitance with no self-healing as the degradation can be extremely high leading to massive failure. If the electrodes are used with fuses in the composition of film capacitors, then the degradation curve will be the one in the green color.

If the fuses are improperly connected to the primary cell can lead to capacitor failure resulting in rapid loss in capacitance. The brown curve is for the high-power film capacitor that has proper segmented electrodes which has considerably higher density due to pure oil impregnation.

These types of film capacitors are designed in such a way that they do not lose more than 2 percent of the original capacitance while working on their rated voltage and current values. This is why these film capacitors tend to have a higher life span than the other types of capacitors and are widely used in AC circuits.

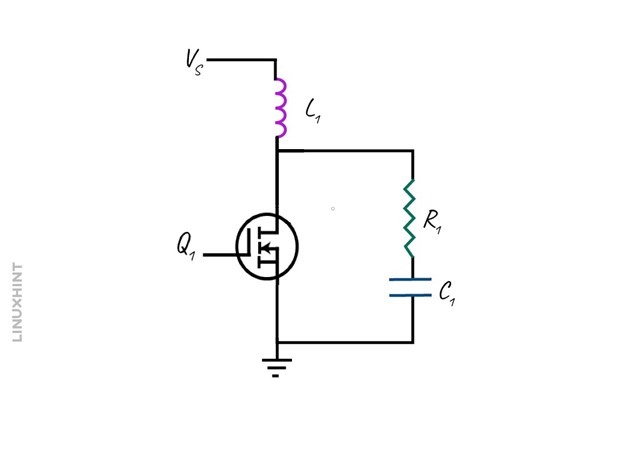

Film Capacitors in Snubber Circuit

Power circuits usually face current and voltage spikes due to higher rates of change of voltages and to deal with such issues snubber circuits are used. Mainly the snubber circuits have film capacitors to reduce the electromagnetic interference and the semiconductor stress. The film capacitor can withstand a higher rate of change of voltage which can cause a higher current to pass through it. So, the dielectric plastic film of polypropylene in the capacitor will be a good match as it has the ability to withstand the voltage and current spikes due to having low equivalent series resistance and inductance:

When the MOSFET is off state the capacitor will charge through the resistor R1 and when the MOSFET is in on state the capacitor will discharge through the resistor and the ground.

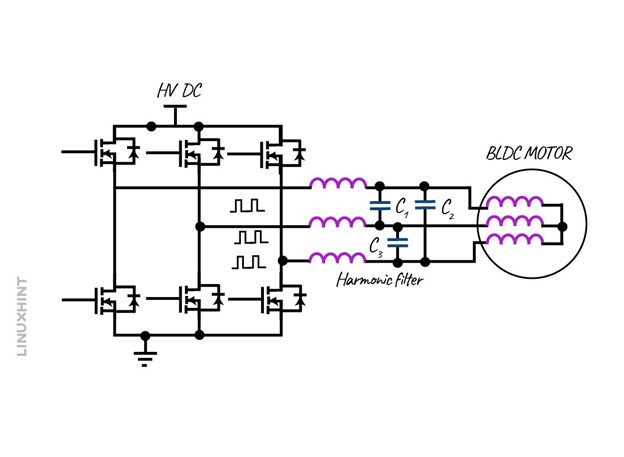

Film Capacitor as Power Filters

To filter out the signals in inverters and motors the capacitors on the output pass the high ripple currents to reduce the levels of rate of change of voltage. This ultimately reduces the stress and the electromagnetic stress in the system. A practical implementation of the film capacitors as the power filter is given below in the circuit:

When an AC supply is connected the capacitors should be non-polarized excluding the use of aluminum electrolytic capacitors.

Film Capacitors as EMI Filters

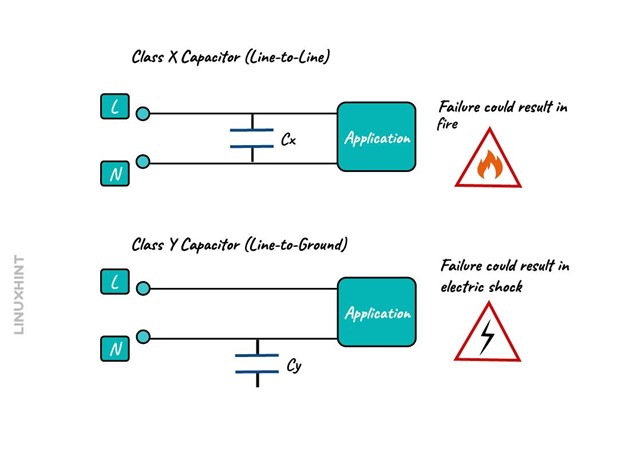

To filter the electromagnetic interference for the circuits the metalized film capacitors are used because of their open circuit failure mode and ability to deal with high voltages. There are two categories of capacitors when connected in power circuits based on their use. The ones with the X label are the capacitors that are connected line to line often named as line to neutral capacitors and are used for differential EMI filtering.

Whereas the capacitors that are connected in line to the ground are categorized as Y and are often named line bypass capacitors. These capacitors bypass the wires to the ground which is called as common EMI filtering mode. Since these capacitors can fail there are special modes in case of failure, that is when the X capacitor fails it creates a short circuit resulting in tripping of the circuit breaker. Moreover, if the Y capacitor fails then it will create an open circuit which minimizes the risk of electric shock.

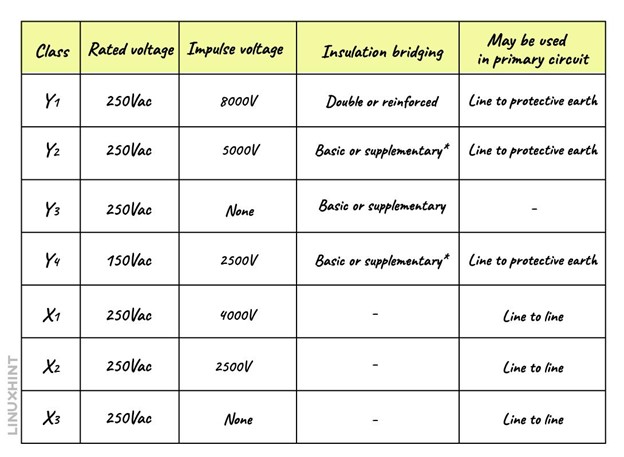

Moreover, in the case of failure of the X capacitor will lead to system shutdown and in case of Y capacitor failure the system will keep on running but the EMI filtering will be reduced. Here is a table below that shows the safety ratings for the capacitors based on their circuit connections:

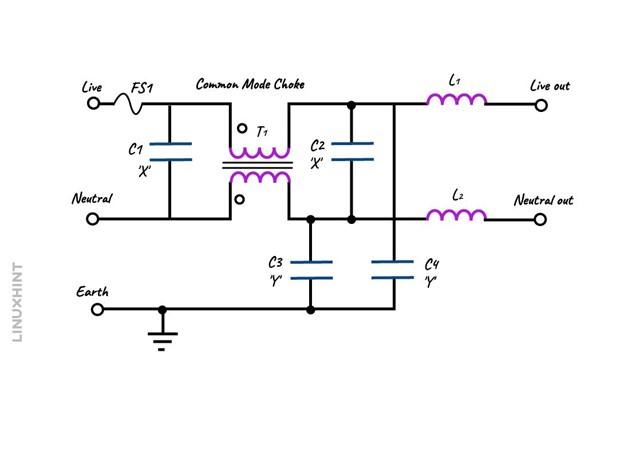

Now to further illustrate the use of film capacitors for EMI filtering here is a simple AC circuit of a power line using the capacitors as EMI filters:

The low self-inductance of film capacitors poses an advantage as it keeps the resonance of the capacitor high. Here the X capacitor is connected between the line and the neutral whereas the Y capacitors are connected between the line and ground.

Conclusion

Film capacitors hold great importance when it comes to power circuits due to their different characteristics and one it is self-healing properties. This property increases the shelf life of the capacitor and also prevents the failure of the system.

Moreover, these film capacitors are divided into types: one is the foil electrode and the other is the metalized film capacitor. Similarly, the film capacitors also vary based on the type of insulating material for the dielectric as the dielectric composition influences the film capacitor’s working characteristics. The film capacitors due to ripple current rating and self-healing feature are preferred over the aluminum electrolytic capacitors.

Source: linuxhint.com